Black Nylon Pvc Part Service Manufacturer CNC Machining Parts

Prototype Machining Service(NoMinimum) Non-standard Parts Customized Service(NoMinimum)

One-stop CNC Machining Service(NoMinimum)

Sheet Metal Fabrication Service(NoMinimum)

Processing:

CNC Milling,CNC Turning,Wire-cut EDM,Precision grinding,Lathe machining,Drilling. Bending,Stamping,Laser Cutting,Broaching. etc.

5.0

like

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Overview: | 1.Tagged price not actual price, requires actual quote;2.Buyers if you want to provide detailed drawings (CAD/DXF format, STP format or tolerance size) can contact our customer service, we can confirm the processing, please feel free to contact me; 3. Custom-ordered products do not support order cancellation |

Description: | CNC Machining or Not:Cnc Machining |

Our Services: | Prototype Machining Service(NoMinimum) Non-standard Parts Customized Service(NoMinimum) One-stop CNC Machining Service(NoMinimum) Sheet Metal Fabrication Service(NoMinimum) |

QC control: | 100% inspection on critical dimensions |

Price: | CNC part factory price |

Why choose us: | Superior quality+on-time delivery+Prompt feedback+competitiv |

Processing: | CNC Milling,CNC Turning,Wire-cut EDM,Precision grinding,Lathe machining,Drilling. Bending,Stamping,Laser Cutting,Broaching. etc. |

Surface: | Anodizing,Sand blasting,Bead Blasting,Powder coating,PaintingAlodine/passivation, treatment zinc plating, silk printing,Laser etching,PolishingTeflon finish,Chrome plating, etc. |

Heat treatment: | Annealing,NormalizingNitriding,TemperingCarbonitriding,etc. |

Tolerance: | ±0.01mm |

Finish: | all kinds of finish available |

Testing equipment: | CMM. Tool microscore. Automatic heiaht gaugeManual height gauge,Digital Micrometer Marble platform,Roughness |

Details Images

Surface treatment | |||

Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

Clear Anodized | Polishing | Zinc plating | Nickel plating |

Color Anodized | Passivating | Oxide black | chrome plating |

Sandblast Anodized | Sandblasting | Nickel plating | Electrophoresis black |

Chemical Film | Laser engraving | Chrome plating | Oxide black |

Brushing | Electrophoresis black | Carburized | Powder-coated |

Polishing | Oxide black | Heat treatment | |

Chroming | Powder Coated | ||

Machining Stainless Steel / Steel Parts

Material: SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling,shot peening,etc.

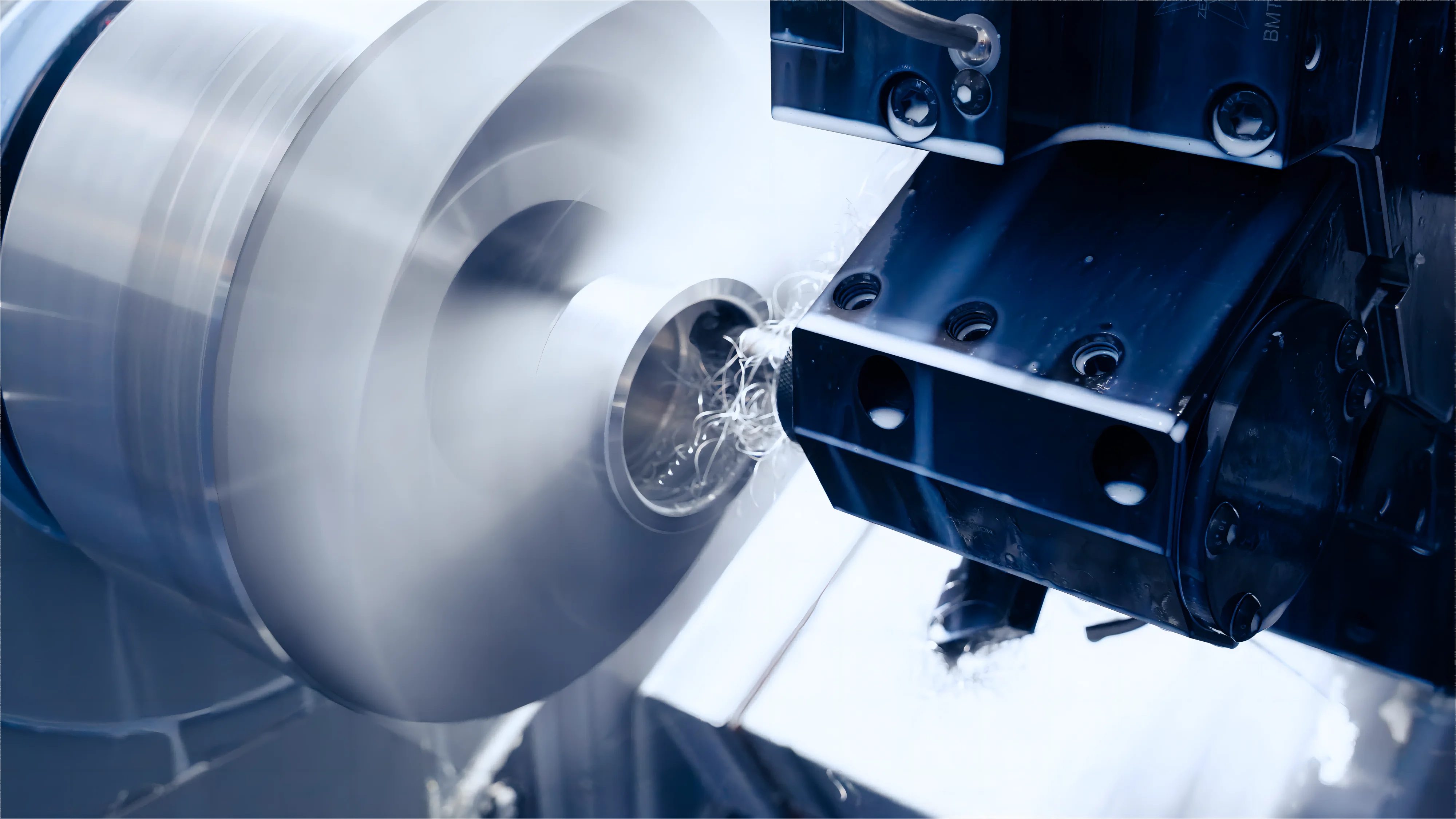

A Machining Process That Rotates a Workpiece While a Cutting Tool Removes Material from the Surface, Suitable for Cylindrical or

Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods. Advantages: High Precision, Repeatability,

And Efficiency in Mass Production.

Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods. Advantages: High Precision, Repeatability,

And Efficiency in Mass Production.

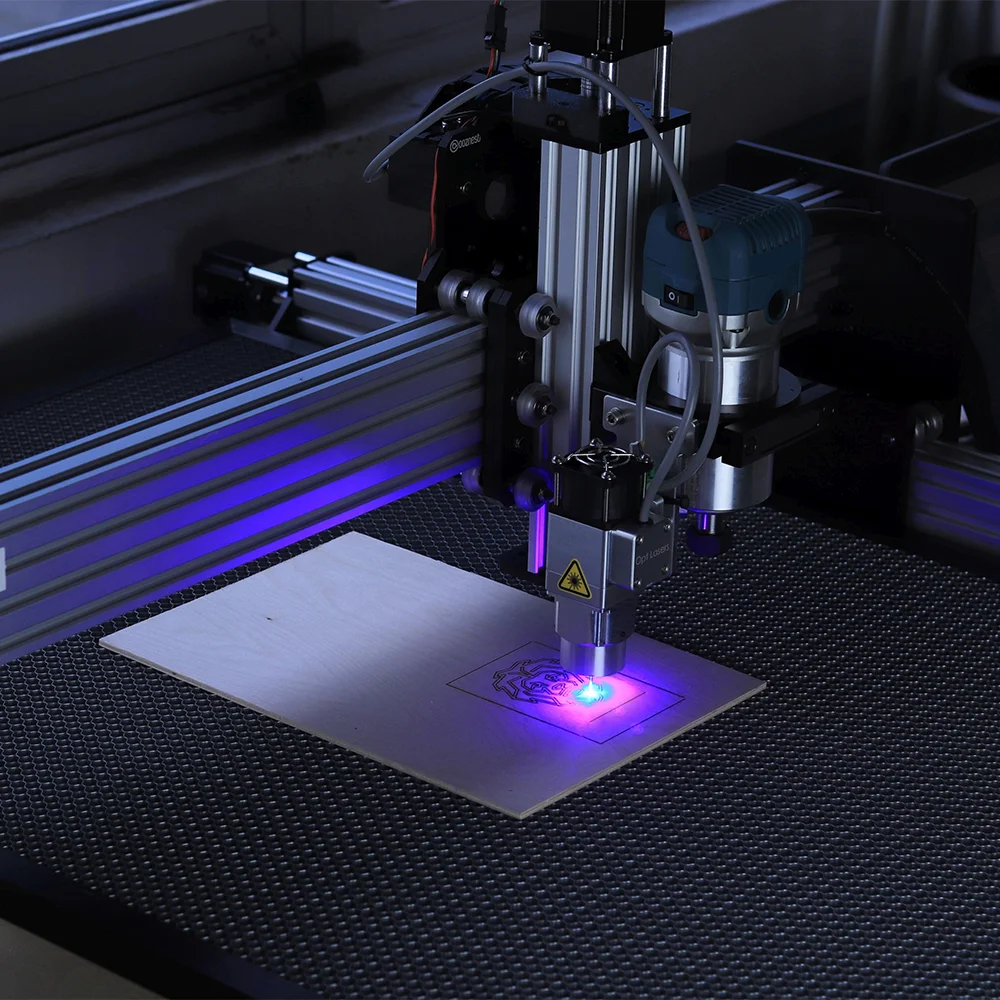

A Machining Process That Uses Rotary Cutters to Remove Material from a Workpiece, Suitable for Flat or Irregularly Shaped Parts

Made of Various Materials Such as Metals, Plastics, And Woods. Advantages: Versatility in Creating Complex Shapes, High Precision,

Repeatability, And Efficiency in Mass Production.

Made of Various Materials Such as Metals, Plastics, And Woods. Advantages: Versatility in Creating Complex Shapes, High Precision,

Repeatability, And Efficiency in Mass Production.

Metal fabrication Processing

1. production machine: laser cutting machine,punching machine, bending machine

2. tolerance: +/-0.1mm

2. tolerance: +/-0.1mm

Stamping

From welding and tapping processes to coatings and assembly, we offers an array of value-added services to accommodate our

clients’ metal stamping projects.

clients’ metal stamping projects.

Surface Finishing

We provides real production-level surface finishing for rapid prototyping & production, such as painting, powder coat,anodized, and chromed finishes.

Our Advantage Services

CHE Hardware manufacturing is a professional manufacturer that focuses on customizing High- Precision Hardware Spare Parts more than 15 years of experience.

We are an expert in different solutions like machinery parts, sensor parts, motorcycle parts, 3d printer&CNC

router parts, auto parts and electrical equipment parts, etc. We have successfully passed the ISO9001 and IATF16949. With a primary thought, we can offer you a one-stop service!

1. Quote Efficiently --- With high efficiency, you can get quotation sheets in 1 hour.

2. Sample L/T --- Samples can be ready in as fast as 30 minutes, MOQ:1pcs.

3. Saving Cost --- Competitive price can minimize your cost

4. R&D Team --- A Professional R&D team with more than 20 years of experience. We can offer you all kinds of customized requirements.

5. Assembly services --- we offer light assembly capabilities in support of our precision machining capabilities. Such sub-assembly, fastening and joining, packag

CNC Machined Parts Surface Treatment:

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

(2) Chemical surface treatment: bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc.

(3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc.

(4) Modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment, etc.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact Us

● We served more than 100,000 customers and exported more than 100+ countries in the world.

● We have 100+ workers and 10+ R&D and quality employees.

Related Products

no data

CHUANGHE INDUSTRIAL(HK) LIMITED Chuanghe Fastener Co, Ltd. (CHE ) offers OEM & ODM & Customized services to customer, which included cold heading, CNC processing center, wire cutting, powder metallurgy processing and assembly of metal parts with plastic parts.We have industry leading quality inspection equipment such as 3D scanner, Ultrasonic Flaw Detector etc

Shortcut links

Contact with us

Tel: +86-186 0769 4667

E-Mail: info2@dgchuanghe.com

Add:

RM302, No.4 building Lizhou industrial Park, Shangshanqi, Zhushan District, Dongcheng Town, Dongguan City, China

FLAT/RM A 15/F GOLDFIELD INDUSTRIAL BUILDING 144-150 TAI LIN PAI ROAD KWAI CHUNG