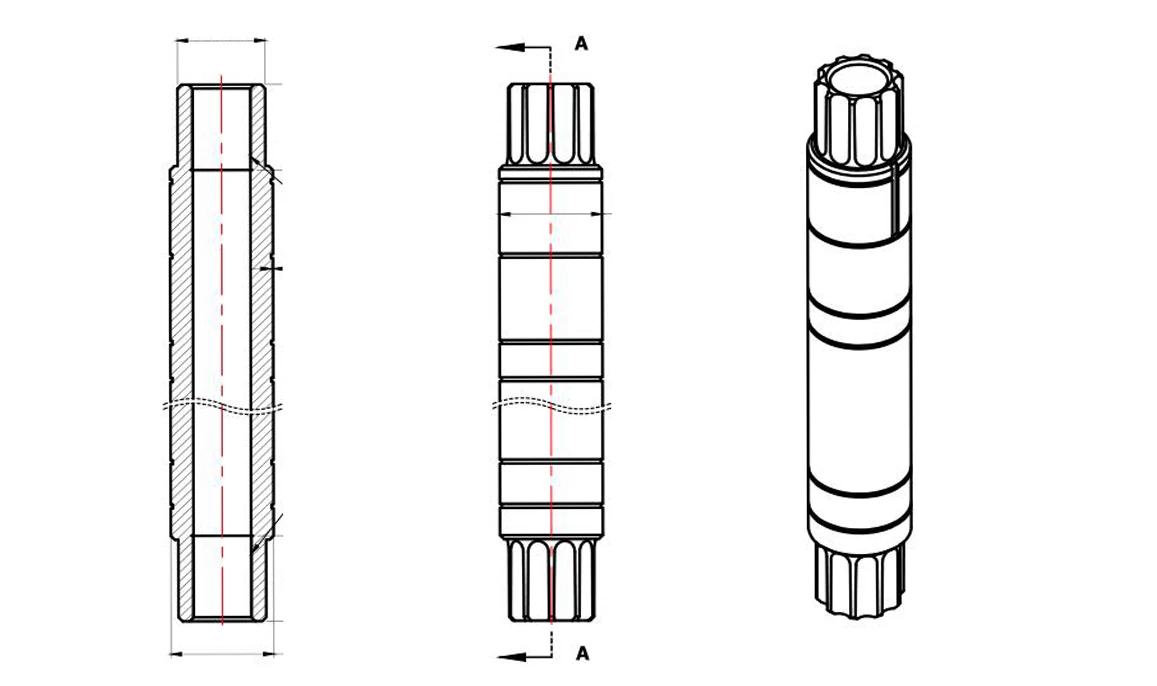

Custom Precision CNC Processing Turning OEM Machining Metal Aluminum Stainless Steel Parts Shaft

•Chrome plated surface, rust resistant durable

•The axial surface is flat, Rotational smoothness

•Extensive application and high precision performance

•Simple installation,All specification can be customized.

•Lighter design, directly pressed into the design to reduce excess material

•Higher precision, reducing errors after installing the crank

•Higher rigidity and bearing capacity strength

2、 ISO 9001 & IATF16949 certified.

3、 15+ years manufacturing experience.

4、 Have rich experience to cooperated with famous brand , like Porsche 、Tesla、Volvo 、Valeo、Paccar...

5、 Providing certificate such as PPAP Level3 、RoHS、MSDS、IMDS etc.

6、 Generally Production lead time is 15 days or even less.

Name | Custom Precision CNC Processing Turning OEM Machining Metal Aluminum Stainless Steel Parts Shaft |

Material | Steel ,Stainless Steel,Carbon steel,Brass,Aluminum or as your requirements |

Size | M1-M36,or non-standard as request&design,Customized Size |

Thread Type | Fine Thread Or Coarse Thread or Hi-Lo Thread |

Finish | Plain, black, zinc plated/according to your requirement |

Standard | ISO,GB,DIN,JIS,ANSI/ASME,BSW,Non-standard. or base on the Drawings or Samples |

Tolerance | 0.01-0.05mm can also be customized |

Design 3D Mould Drawing | • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity •Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt |

Certificate | ISO9001,ISO14001,IATF16949, ROHS |

Surface treatment | zinc plated,Ni-plated,Passivated,Black Oxide,Bronze |

Advantage | OEM Customized Service Provided |

USE | Mountain bike ,Automobile, aviation, new energy, high-speed rail |

Packing | Cartons+plastic Bags |

Pin shaft

installing the crank 3. Higher rigidity and bearing capacity strength

Spindle

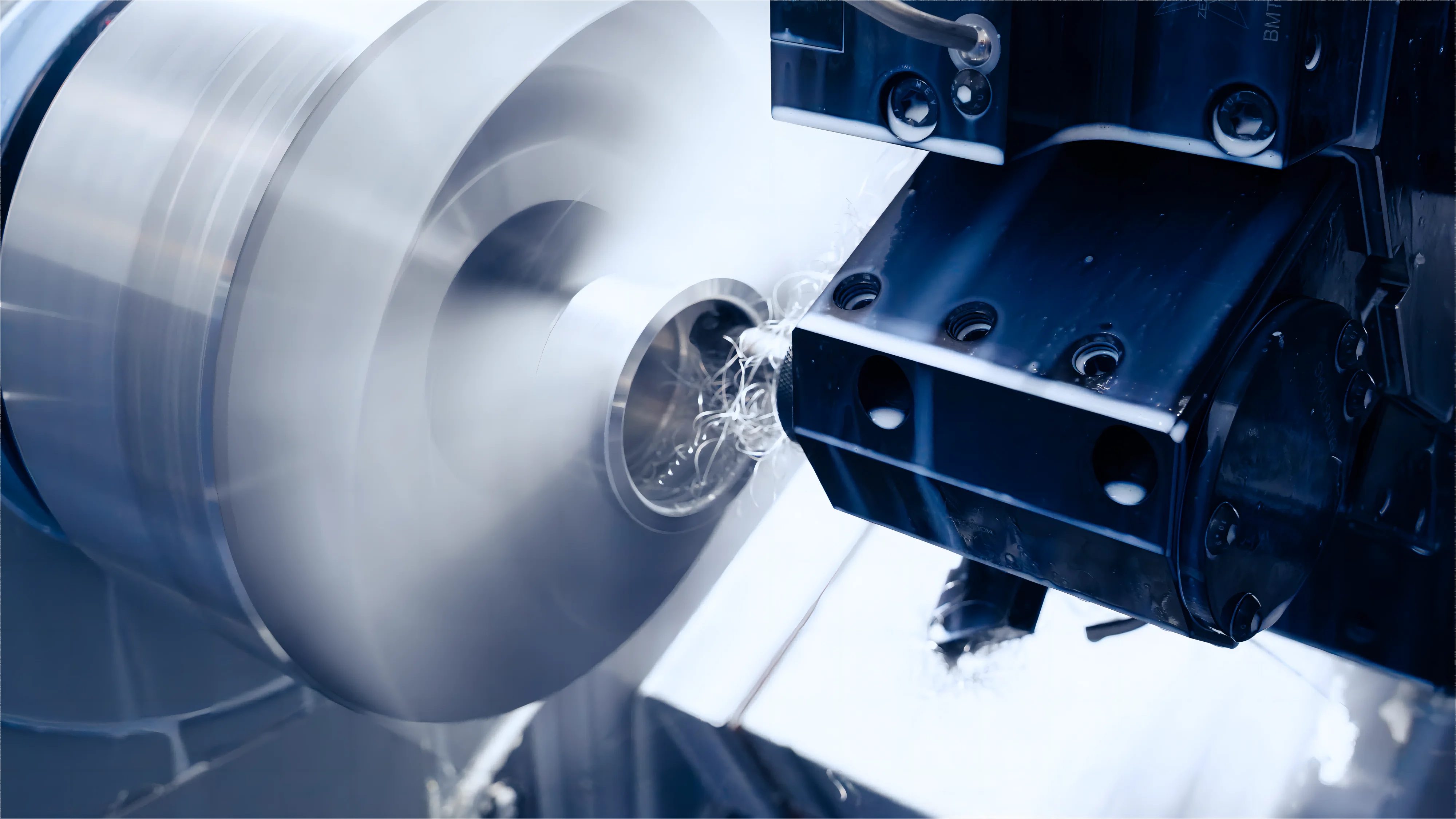

CNC Turning

Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods. Advantages: High Precision, Repeatability,

And Efficiency in Mass Production.

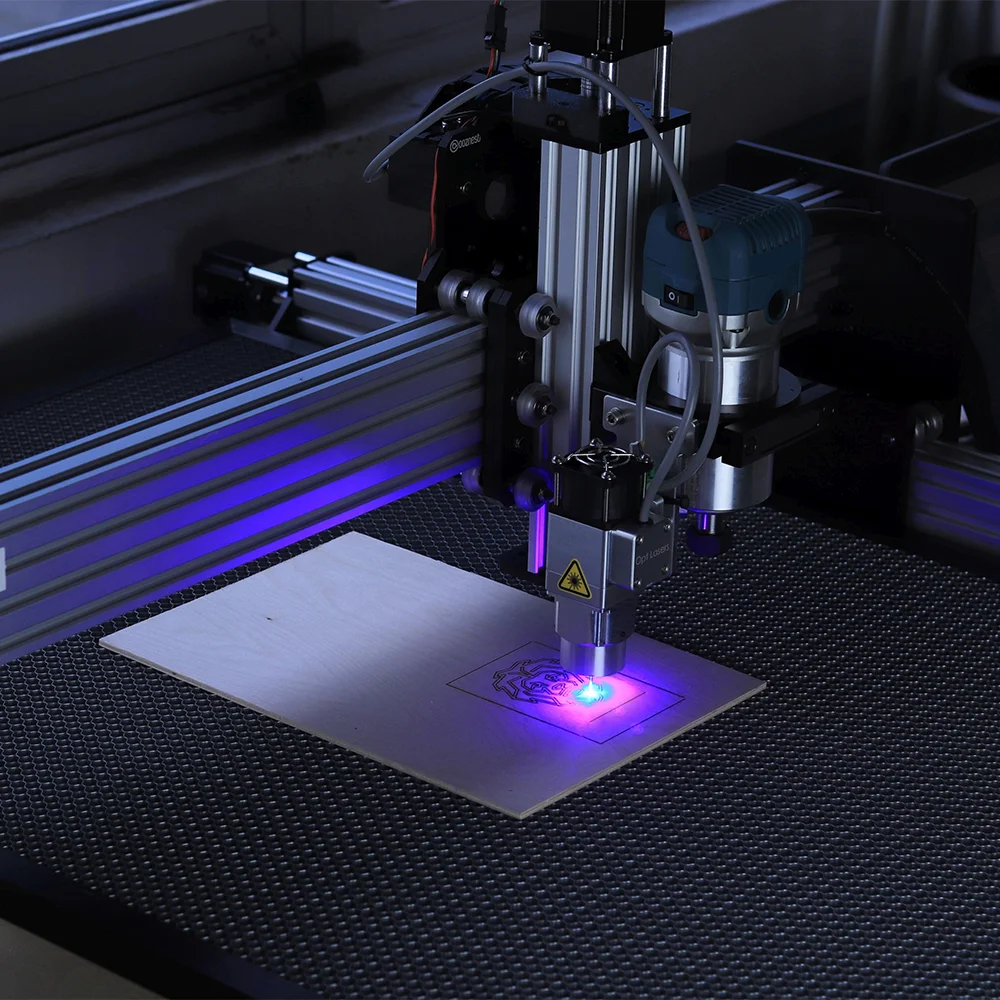

CNC Milling

Made of Various Materials Such as Metals, Plastics, And Woods. Advantages: Versatility in Creating Complex Shapes, High Precision,

Repeatability, And Efficiency in Mass Production.

Metal fabrication Processing

2. tolerance: +/-0.1mm

Stamping

clients’ metal stamping projects.

CHUANGHE INDUSTRIAL(HK) LIMITED Chuanghe Fastener Co, Ltd. (CHE ) offers OEM & ODM & Customized services to customer, which included cold heading, CNC processing center, wire cutting, powder metallurgy processing and assembly of metal parts with plastic parts.We have industry leading quality inspection equipment such as 3D scanner, Ultrasonic Flaw Detector etc